-40%

PLC Training Course Covers Allen Bradley Products DVD's

$ 34.32

- Description

- Size Guide

Description

RSLogix 500 1,2,&3training DVD, RSLogix 5000 1,2,&3 training DVD, PanelBuilder 32 training videos, and the PLC Automation DVD with the simulator. Plus you get the RS500Advanced training video, UL 508A, and VFD training DVD's(7) DVD's this course will take you 30 days to complete.This course was recorded on VHS tapes and then transferred to DVD's, theresolution is not the highest, and there are some areas that are hard to read.Note the material is excellent, and if you take your time you will learn a lot.I have been programming for over 20+ years and I put it all in these DVD's. TheAdvanced RS500 and PB32 videos have very high resolution video. This producthas it all!

Training videos are burned on new blank DVD's.

RS5K#1: PLC Course Using RS Logix 5000.

CourseOverview

·

What is a PLC?

·

The numbering systems.

·

Logic Gates

·

Applying Programming Strategies andTechniques using RS Logix 5000.

·

Getting Started with RS Logix 5000

·

Documenting and Searching LadderLogix using RS Logix 5000 Program.

·

Programming Timer and CounterInstruction using RS Logix 5000.

·

Drafting Ladder Logic for an RSLogix 5000 Project.

RS5K#2: PLC Course Using RS Logix 5000.

CourseOverview

·

Homework review from RS5K #1 DVD.

·

Combinational Logic and examplesusing RS Logix 5000.

·

Sequential Logic and examples usingRS Logix 5000.

·

State Diagrams and examples using RSLogix 5000.

·

Integrated Practice - ProgrammingBasic Instructions using RS Logix 5000.

·

Programming Program ControlInstructions using RS Logix 5000.

·

Programming CompareProgramming Instructions using RS Logix 5000.

·

Configuring the analog cards, andsetting up the built in alarm features.

·

Drafting Ladder Logic for an RSLogix 5000 Project.

RS5K#3: PLC Course Using RS Logix 5000.

CourseOverview

·

Homework review from RS5K DVD#2.

·

JK Flip Flops and examples using RSLogix 5000.

·

T-Flip Flops and examples usingRS Logix 5000.

·

Karnaugh (K-Maps) and examplesusing RS Logix 5000.

·

Integrated Practice - ProgrammingBasic Instructions using RS Logix 5000.

·

Monitoring and EditingTags using RS Logix 5000.

·

Forcing and Toggle Bits usingRS Logix 5000.

·

Troubleshooting ControllerProblems using RS Logix 5000.

·

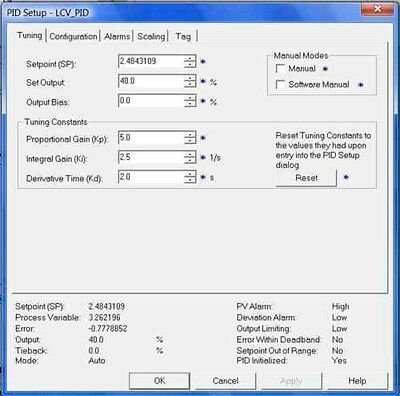

Configuring the analogcards, setting up a PID instruction.

·

ISA Symbols and examples using RSLogix 5000.

·

Drafting Ladder Logic for an RSLogix 5000 Project.

RS500#1: PLC Course Using RS Logix 500.

CourseOverview

·

What is a PLC?

·

The numbering systems: binary,octal, and hexidecimal.

·

Logic Gates

·

Identifying PLC system components,selecting your system.

·

Getting Started with RS Logix 500

·

Downloading, Going on line, andsaving a RS Logix 500 Program.

·

Determining Addresses and assigningComments and Symbols using RS Logix 500.

·

Drafting Ladder Logic for an RSLogix 500 Project.

RS500#2: PLC Course Using RS Logix 500.

CourseOverview

·

Quick review of the topics coveredin RS500#1 DVD detailed solutions are given for the homework given.

·

1's and 2's complement notation

·

Combinational Logic

·

Karnaugh Maps

·

DeMorgans Law

·

Sequential Logic

·

Operating Systems

·

Downloading and running a RS Logix500 simulator

·

Selecting Bit Instructions

·

Entering, Editing, and VerifyingLadder logic

·

Determining Program Flow andCreating Subroutines

·

Selecting and Programming TimerInstructions

·

Selecting and Programming CounterInstructions

·

Entering and Searching forDocumentation

RS500#3: PLC Course Using RS Logix 500.

CourseOverview

·

Quick review of the topics coveredin RS500#2 DVD, detailed solutions are given for the homework given.

·

Sequential Logic and Completion ofFlip Flop Circuits

·

Karnaugh Maps 3, and 4 variablek-maps

·

Karnaugh Maps 5,and 6 variable k-maps

·

Quine-McCluskey Method

·

Reduction of State Tables

·

Introduction to State Machine Design

·

Organizing the Data Table

·

Selecting and programming MathInstructions

·

Selecting and Programming DataHandling Instructions

·

Selecting and Programming ComparisonInstructions

·

Configuring and Previewing a ProjectPrintout

Howto do the above courses:

Whenyour PLC training product arrives first watch RS500 #1 DVD in a regular TV witha DVD player. If you need to watch it on a PC then load this softwarehttp://www.videolan.org/ After you have watched RS500#1 DVD then do thehomework for RS500 #1. Do not skip around and take your time. Onceyou complete RS500 #1 homework then watch RS500#2 DVD; then do the homework for#2. Continue this until you finish RS500#3. Then repeat thisprocess for the RS5K #1. Let me know if you still have questions afterwatching the DVD's and doing the homework.

*********************************************************************

PLC Automation is Included

CompleteCollege Undergraduate Level PLC / Automated ManufacturingSystems Training Course

onDVD

ACOMPLETE COLLECTION OF ENTRY LEVEL - ADVANCED PLC TRAINING &REFERENCE BOOKS CONVENIENTLY ARRANGED ON DVD

INVALUABLE INTERACTIVEPLC PROGRAMMING SIMULATION SOFTWARE LINK

THE CONTENTSOF THIS COLLECTION ON DVD INCLUDE:

•

PLC / AUTOMATION TRAINING TITLES:

◦

PLC Primer

(16 pages) - An Introduction to PLC's (Learn theBasics)

▪

What is a PLC?

▪

Why Use PLCs?

▪

But What Exactly Is a PLC?

▪

A little More About Inputs and Outputs

▪

And a Little More About the Control Program

▪

So How Does a OLC Keep All This Straight?

▪

To Sum It All Up

▪

Want To Learn More?

◦

AutomatedManufacturing Systems: PLC's

(894 pages) - A College Level UndergraduateTextbook on PLC Based Control Systems

▪

Programmable Logic Controllers

▪

PLC Hardware

▪

Logical Sensors

▪

Logical Actuators

▪

Boolean Logic Design

▪

Karnaugh Maps

▪

PLC Operation

▪

Timers, Counters and More

▪

Structured Logic Design

▪

Flowchart Based Design

▪

State Based Design

▪

Numbers and Data

▪

PLC Memory

▪

Ladder Logic Functions

▪

Advanced Ladder Logic Functions

▪

Open Controllers

▪

Instruction List Programming

▪

Structured Text Programming

▪

Sequential Function Charts

▪

Function Block Programming

▪

Analog Inputs and Outputs

▪

Continuous Sensors

▪

Continuous Actuators

▪

Continuous Control

▪

Fuzzy Logic

▪

Serial Communication

▪

Networking Communication

▪

Internet

▪

Human Machine Interfaces (HMI)

▪

Electrical Design

▪

Software Design

▪

Selecting a PLC

▪

Appendix - Function References

▪

Appendix - Glossary

▪

Appendix - References

◦

Dynamic System Modeling & Control

(943 pages) - AnIntroduction to the Basic Concepts of System Modeling With Different Equations

▪

Introduction

▪

Translation

▪

Solving Differential Equations

▪

Numerical Methods

▪

Rotation

▪

Transfer Functions

▪

Circuits

▪

Feedback Control Systems and Block Diagram

▪

Phasor Analysis

▪

Bode Plots

▪

Root Locus Plots

▪

Non-linear Systems

▪

Analog IO

▪

Sensors

▪

Actuators

▪

Motion Control Systems

▪

Laplace Techniques

▪

Magnetic Systems

▪

Fluids

▪

Linear Controls with Laplace

▪

Lab Guide

▪

Writing

▪

Math Review Guide

▪

C Programming Review

▪

Units

▪

Materials

◦

Integration & Automation of Manufacturing Systems

(593pages) - In Depth Programming Guide Using Linux & OtherUseful Platforms (Programming Information not Found in Other Automation BooksAvailable)

▪

Integrated and Automated Manufacturing

▪

An Introduction to C/C++ Programming

▪

Network Communication

▪

Databases

▪

Communications

▪

Programmable Logic Controllers (PLCs)

▪

PLCs and Networking

▪

Industrial Robotics

▪

Other Industrial Robots

▪

Robot Applications

▪

Spatial Kinematics

▪

Motion Control

▪

CNC Machines

▪

CNC Programming

▪

Data Acquisition

▪

Vision Systems

▪

Integration Issues

▪

Material Handling

▪

Petri Nets

▪

Production Planning and Control

▪

Simulation

▪

Planning and Analysis

▪

References

▪

Appendix - Projects

▪

Appendix - Common References

•

PLC / AUTOMATION REFERENCE TITLES:

◦

Electrical Relay Diagram & P&ID Symbols (

5 pages) - AReference Table of Relay & P&ID Symbols Used in Design

▪

Disconnect

▪

Circuit Interrupter

▪

Circuit Breaker

▪

Limit Switches

▪

Proximity Switches

▪

Liquid Level switches

▪

Vacuum & Pressure

▪

Temperature

▪

Flow (Air, Water)

▪

Foot switches

▪

Toggle

▪

Cable Operated (Emerg.)Switch

▪

Plugging

▪

Nonplug

▪

Selector

▪

Rotary Selector

▪

Thermocouple Switch

▪

Push Buttons

▪

Total Contacts To Suit Needs

▪

Contacts

▪

Coils

▪

Control Circuit Transformer

▪

Motors

▪

Pilot Lights

▪

Horns, Siren, Etc.

▪

Buzzer

▪

Bell

▪

P&ID Symbols

▪

Instrument Identification Lettering

◦

Logic Symbols, Truth Tables & Equivalent Ladder Logic Diagrams

(2pages)

-

A Programmers Quick Reference Cardfor Implementing Boolean Logic in Ladder Programs

▪

AND

▪

OR

▪

XOR

▪

NAND

▪

NOR

◦

Programming & Documentation Pads

(8 pages) - AnAssortment of Useful PLC Listing Pads Allowing Better PLC Design Implementation& the Ability to Keep an Orderly Documentation System

▪

Input/Output Listing

▪

PLC Automation Project Notes

▪

PLC Program Listing

▪

Register-Word/Internal Output Usage Listing

◦

PLC Glossary of Terms

(25 pages) - A Complete Glossary ofthe Most Commonly Used Terms in PLC Systems

▪

Complete listing of Terms

•

INTERACTIVE PLC SIMULATOR SOFTWARE LINK:

◦

PLC Ladder Logic Editor - Allows Users to Create & Edit PLCPrograms using Allen Bradley PLC-2 Family Instructions

◦

Scanning Sequence Emulator - When Placed in "RUN" Modethe Users Programming is Scanned & the Appropriate I/O is Updated Just asWould Occur un an Actual PLC

◦

Multiple Animated Simulations - Life-Like AnimatedSimulations Respond Accurately to the I/O of theStudents Emulated PLC Programming

◦

The simulation software is provided on a DVD via a link.

SIMULATEDPROCESSES:

◦

Automated Filling System

▪

Operator Station Panel and controls

▪

Conveyor with position sensors (photo switch)

▪

Hopper with motorized chute control

▪

Product Level Sensor

▪

Conveyor Motor

▪

Visual PLC Data Table Display including timers and counters

◦

Batch Mixing system Simulation

▪

Operator Control Panel

▪

2 filler pumps and piping

▪

2 flow meters on filler lines

▪

1 mixing motor

▪

1 high level sensor

▪

1 low level sensor

▪

1 gas fired heater (controlled valve)

▪

1 temperature sensor

▪

1 discharge pump

▪

1 discharge flow meter

▪

1 Visual PLC Data Table display including timers and counters

◦

Intersection Traffic Light Control Simulation

▪

2-way traffic lights system

▪

2 Green Lights

▪

2 Red Lights

▪

2 Amber Lights

▪

Visual PLC Data Table Display including timers and counters

▪

2 way traffic flow

◦

Hardware Input and Output Simulator

▪

4 toggle switches (SPST)

▪

2 momentary normally open switches

▪

2 momentary normally closed switches

▪

8 controllable lights

▪

Visual PLC Data Table Display including timers and counters

▪

The simulation software is provided on a DVD via a link.

PanelBuilder32Training videos are Included:

Thesevideos will train you on how to program a PanelView operator interface usingAllen Bradley PanelView32.

ThePanelView 32 replaces lights, meters, etc... Everything can be displayed on theHMI (human interface module) or OIT (operator interface terminal).

Youare not buying the actual screens in the picture; you are buying trainingvideos to learn how to program PanelBuilder32.

Thevideos cover the following:

•

Overview of PanelView Screens

•

Communications Overview

•

Panelbuilder basics

•

Working with Applications and Screens

•

Working with objects

•

Creating Pushbuttons

•

Creating Control list selectors

•

Creating Screen Selectors

•

Creating Bar Graphs, indicators and numeric displays

•

Creating Message Displays

•

Using Global Objects

•

Creating Alarms

•

Formatting Objects and text

•

Using the text editor

•

Working with Tags

•

Terminal and Communication setup

Thiscourse focuses on the standard panel view screens.

PLUSYOU GET THE RS500 ADVANCED Videos!

AdvancedPLC course putting it all together!

RSLogix 500 + QuickPanel Designer + PanelBuilder32

Upto this point we have focused on the basics. Due to a high number ofrequests

http://ibtti.yikesite.com/

has created a course that willtake the conceptual idea, and or P&ID diagrams and start creating the codefrom the very beginning all the way to communicating to an HMI (5" colorTotal Control Products) and an (Allen Bradley Micro 300); as well as cover thenetworking capabilities of creating the code for the PLC to communicate to aModbus RTU master emulator.

Thisis an advanced course that will allow the programmer to go from a basic levelto a more advanced level. This is not an easy course but if you are readyfor the next level here it is. There is over 8 hours of livetraining.

This videocourse comes on a DVD and has the necessary supplementary PDF manuals. Ifyou send me your completed code and answer a few questions we can issue you acertificate of completion via email.

Minimum HARDWARE / SOFTWARE REQUIREMENTS:

IBM.®486 or higher compatible computer

•

Windows® 95 or greater

•

Minimum 640k of RAM

•

Hard disk drive

•

DVD

•

800 x 600 or higher screen video capability

Whybuy pre-recorded materials like this course? If you watch the course again anddo the homework again; you will see more items that were missed the first time.The reason is your mind catches an idea; you begin thinking of this idea; andthen when you get back to the DVD some items have already passed. By watchingthis course 3 times and doing the homework 3 times you will have mastered thesePLC programming skills. A refresher on an annual basis is not a bad ideaeither.

How to do this course:

NOTE:The Qty. (5) CD’s have been converted to Qty (1) DVD.

Qty(1) PLC Training DVD; has Panelbuilder 32, RS Logix 500 Advanced, PLCAutomation CD, RS Logix 500 supplementary CD, as well as the RS Logix 5000supplementary CD.

Whenyour PLC training product arrives first watch RS500 #1 DVD in a regular TV witha DVD player. If you need to watch it on a PC then load thissoftware

http://www.videolan.org/

After you have watched RS500#1DVD then do the homework for RS500 #1. Do not skip around and take yourtime. Once you complete RS500 #1 homework then watch RS500#2 DVD; then dothe homework for #2. Continue this until you finish RS500#3. Thenrepeat this process for the RS5K #1, 2 & 3. Move to the PLC TrainingDVD and watch the videos. Let me know if you still have questions afterwatching the DVD's.